- Machinery

- Stuffing & clipping

- Automatic multifunction

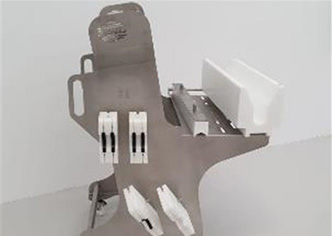

- LAPEG 1200XXL

LAPEG 1200XXL Uniform length for each piece

- Length of the piece adjustable via a control panel.

- Uniform length and weight.

- Higher throughput due to high meat compaction.

- Maximum performance in the filleting process.

Description

LAPEG 1200XXL

This machine allows to stuff products which need to be positioned before being stuffed.

The capacity of the mould in length is 700mm, with the possibility to adapt it to the customer’s needs.

The machine consists of 3 parts:

1. AUTOMATIC LOADER FOR THE PRODUCT POSITIONING:

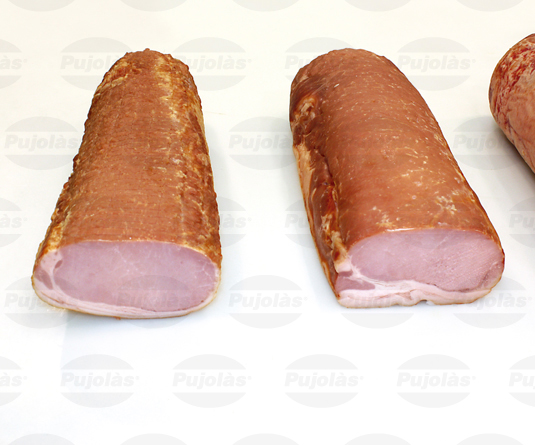

The main aim of this loader is to properly place the product into the mould, i a way that when this gets to the stuffer, it has not moved and keeps the original shape and positioning. This loader can be changed as many times as needed, depending on the diameter we wish to staff. The stuffing diameter will vary from Ø 60 to Ø 220 (for bigger calibres, please contact the manufacturer).

2. STUFFING MACHINE:

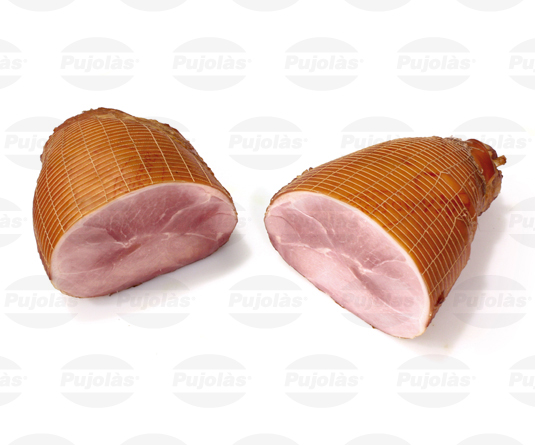

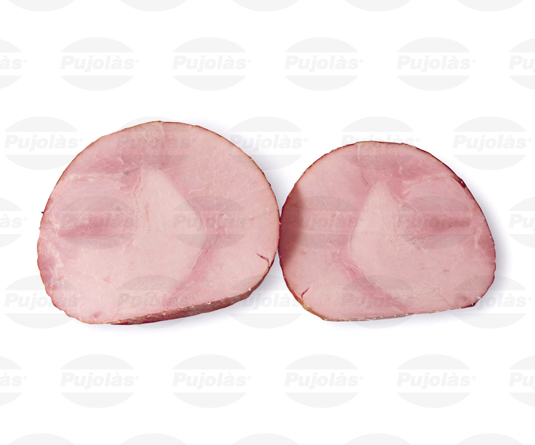

The stuffing machine is the one that gives shape to the product, and it also puts the product into the net, plastic or casing.

3. TENSING-CLIPING MACHINE:

This machine is the one that puts the clips at each side of the product, and also a piece of cord in case this is required. The machine has got an automatic system of Tension and Clipping. It is also possible to adjust the tension on the product automatically.

-

2300x3040x6070 mm

-

2300 kg

-

Why Pujolàs

-

For production capacity Facilities

3,500 m2 devoted exclusively to manufacturing, plus a further 800 m2 for offices, a technical area, electronics and software department, the technical department and the Pilot Plant.

-

For high technology Constant innovation

The R&D department researches and designs innovative machines to optimise processes and make our customers more competitive. Our team is constantly working to achieve excellence without compromising quality, sustainability or respect for the product.

-

For our service Performance and commitment

We offer solutions that are tailored to your needs so you can get the most out of the final product